Behind the Scenes | Challenges, Rewards in Producing Handcrafted Lighting

Every day, dozens of hands touch the raw materials that are carefully crafted into Barn Light Electric’s American-made lighting. These hands cut, mold, paint, clean, polish, and assemble the pieces as our artisans fully embrace the handcrafted nature of the business.

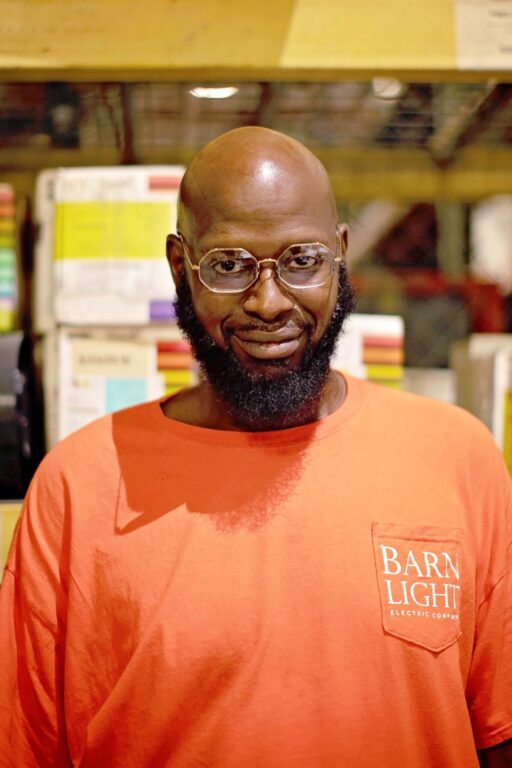

Today, we are spotlighting Rob who will be celebrating his 5th year with Barn Light in August. Rob has lived in Florida for more than 16 years and first started working as a galvanizer in the coatings department.

“After about a year of galvanizing fixtures, I moved to shipping where I worked for two years,” Rob says. “I helped out in other departments whenever needed as well.” Two years ago, Rob was promoted to Lead of Barn Light’s powder coat department where he manages a team of seven. As customers build their light fixtures online during the ordering process, they choose either a powder coat or porcelain enamel finish. Rob’s team handles the powder coat orders which accounts for about 70 percent of the materials moving through the plant each day.

“On a typical day, I input orders being handled in our department as well as load and unload parts in the oven,” Rob explains. “I organize orders by color as well as date, plus clean, rack, de-rack, and move parts to be sprayed.” With 28 powder coat colors offered currently, the team stays busy moving shades, gooseneck arms, and hardware through the work area to be sprayed, baked, then passed on to assembly.

“The main objective in being the coatings Lead is being flexible,” Rob notes. “What once was a small company operating in a garage is now a large organization working in a 60,000-square-foot facility and shipping product worldwide.” Rob adds that the hardest part about his job is consistency in producing quality parts and being able to work in the Florida heat.

“We get to see the parts and work with them before the light is built — just the shade, just the gooseneck arm, or the backing plate,” he says. “But I enjoy working in coatings because you see the creativity in the lights. Being a part of one of Barn Light’s main departments is awesome!”

I’m so proud of this young man. He’s my nephew. A hard worker and family oriented. Rob you can achieve anything that you put your heart and mind to. Remember you can do all things through Christ that strengthens you.

Thanks Marilyn! We are so blessed to have Rob on our team!

Robert I’m so proud of you and everything you have accomplished you are such a hard worker. And a very loving husband and a wonderful father thank you for always providing for us the way you do.

Keep up the great work Cuz!!

I am Robert’s Mother, I am very proud of the Man, Husband, and Father he has become he always had a very strong work ethic, strong mind and very intelligent, Keep Striving for greatness.

I’m so very proud of my nephew. Keep up the great work Big Rob.